NanoLight claims to be world's most efficient light bulb.

The NanoLight LED’s are directly attached to a printed circuit board that is folded to resemble the stereotypical light bulb shape

Until recently LED light bulb manufacturers have struggled to find a solution in the 75 to 100-watt range which successfully replaces the soon-to-be redundant, energy crunching 100 W incandescent bulb in terms of size and brightness. Three friends from the University of Toronto are the latest to offer a feasible product to match the classic 100 W bulb without compromising on electricity consumption with their proposed NanoLight LED light bulbs.

Gimmy Chu, Tom Rodinger and Christian Yan of NanoLight met during a university solar car project back in 2005. With a shared enthusiasm for sustainable products they joined forces again three years ago and aim to launch three models of the Nanolight in the near future through the funding platform Kickstarter. The trio hopes their products will prove that true 100 W equivalent LED lighting can be achieved and that NanoLight can make good its claim as “the worlds most energy efficient light bulb.”

NanoLight’s signature product is a 12 W LED bulb that provides the equivalent of a 100 W classic bulb and gives off 1600 lumens. Whilst the 60 W LED range has proved successful, manufacture of higher wattage equivalents that fit into current light fixtures has been difficult. LED lights produce less heat then traditional bulbs, but this heat becomes an issue that shortens the lifespan and efficiency of the LEDs when the volume is increased for a higher wattage effect.

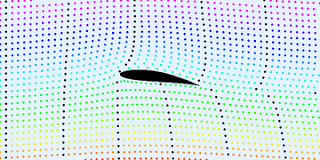

The NanoLight products claim to have addressed the LED heat issues and are also billed as omnidirectional, which is not a feature of the average LED bulb. The NanoLight LED’s are directly attached to a printed circuit board that is folded to resemble the stereotypical light bulb shape. The product testing that can be seen in the videos below shows that the LEDs withstand the heat issues within this format.

Although manufactured electronic circuit boards are well established, the folded design of the NanoLight will provide challenges for the team. Using surface mounting technology, the individual components will be placed into predefined positions and will require a low temperature soldering process to secure the components. Once this has been achieved a process will take place to assemble the circuit board into its bulb shape and secure on the screw base light fitting which is the current available option

.

The alternative to a 100 W incandescent bulb has until recently been a compact fluorescent light, if you have the time for them to warm up to maximum light output. The LED is a much more pleasing alternative not only for using less harmful materials during manufacture, but also by providing an instant warm neutral white full light on request and lasting a lot longer with an estimated lifespan of 30,000 hours.

In addition to the 12 W NanoLight, a 10 W NanoLight (75 W equivalent) and a 12 W NanoLight (1800+ Lumens) are also in the pipe. These three models are available in 120V AC and 220-240V AC versions to cater to different geographic regions. The NanoLight team has also received high demand for a dimmable version and are already working on a prototype model that can achieve this.

Despite this, NanoLight estimates that over a period of 30,000 hours of usage an LED bulb can save a consumer around seven times the expense of an equivalent periods usage of incandescent bulbs.

Other recent (and heavyweight) entrants into the 100-watt equivalent LED market include the Phillips 22 W LED and the 20 W bulb from Osram Sylvania, a division of Germany's Siemens AG.

The video below provides more information on the production and testing of the NanoLights.

The NanoLight LED’s are directly attached to a printed circuit board that is folded to resemble the stereotypical light bulb shape

Until recently LED light bulb manufacturers have struggled to find a solution in the 75 to 100-watt range which successfully replaces the soon-to-be redundant, energy crunching 100 W incandescent bulb in terms of size and brightness. Three friends from the University of Toronto are the latest to offer a feasible product to match the classic 100 W bulb without compromising on electricity consumption with their proposed NanoLight LED light bulbs.

Gimmy Chu, Tom Rodinger and Christian Yan of NanoLight met during a university solar car project back in 2005. With a shared enthusiasm for sustainable products they joined forces again three years ago and aim to launch three models of the Nanolight in the near future through the funding platform Kickstarter. The trio hopes their products will prove that true 100 W equivalent LED lighting can be achieved and that NanoLight can make good its claim as “the worlds most energy efficient light bulb.”

NanoLight’s signature product is a 12 W LED bulb that provides the equivalent of a 100 W classic bulb and gives off 1600 lumens. Whilst the 60 W LED range has proved successful, manufacture of higher wattage equivalents that fit into current light fixtures has been difficult. LED lights produce less heat then traditional bulbs, but this heat becomes an issue that shortens the lifespan and efficiency of the LEDs when the volume is increased for a higher wattage effect.

The NanoLight products claim to have addressed the LED heat issues and are also billed as omnidirectional, which is not a feature of the average LED bulb. The NanoLight LED’s are directly attached to a printed circuit board that is folded to resemble the stereotypical light bulb shape. The product testing that can be seen in the videos below shows that the LEDs withstand the heat issues within this format.

Although manufactured electronic circuit boards are well established, the folded design of the NanoLight will provide challenges for the team. Using surface mounting technology, the individual components will be placed into predefined positions and will require a low temperature soldering process to secure the components. Once this has been achieved a process will take place to assemble the circuit board into its bulb shape and secure on the screw base light fitting which is the current available option

.

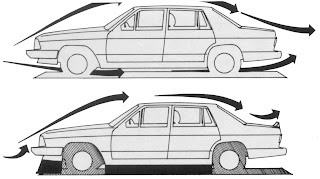

The NanoLight operates at 133 lumens per watt - the above chart shows the company's own comparison to other light bulbs on the market

In addition to the 12 W NanoLight, a 10 W NanoLight (75 W equivalent) and a 12 W NanoLight (1800+ Lumens) are also in the pipe. These three models are available in 120V AC and 220-240V AC versions to cater to different geographic regions. The NanoLight team has also received high demand for a dimmable version and are already working on a prototype model that can achieve this.

Despite this, NanoLight estimates that over a period of 30,000 hours of usage an LED bulb can save a consumer around seven times the expense of an equivalent periods usage of incandescent bulbs.

Other recent (and heavyweight) entrants into the 100-watt equivalent LED market include the Phillips 22 W LED and the 20 W bulb from Osram Sylvania, a division of Germany's Siemens AG.

The video below provides more information on the production and testing of the NanoLights.